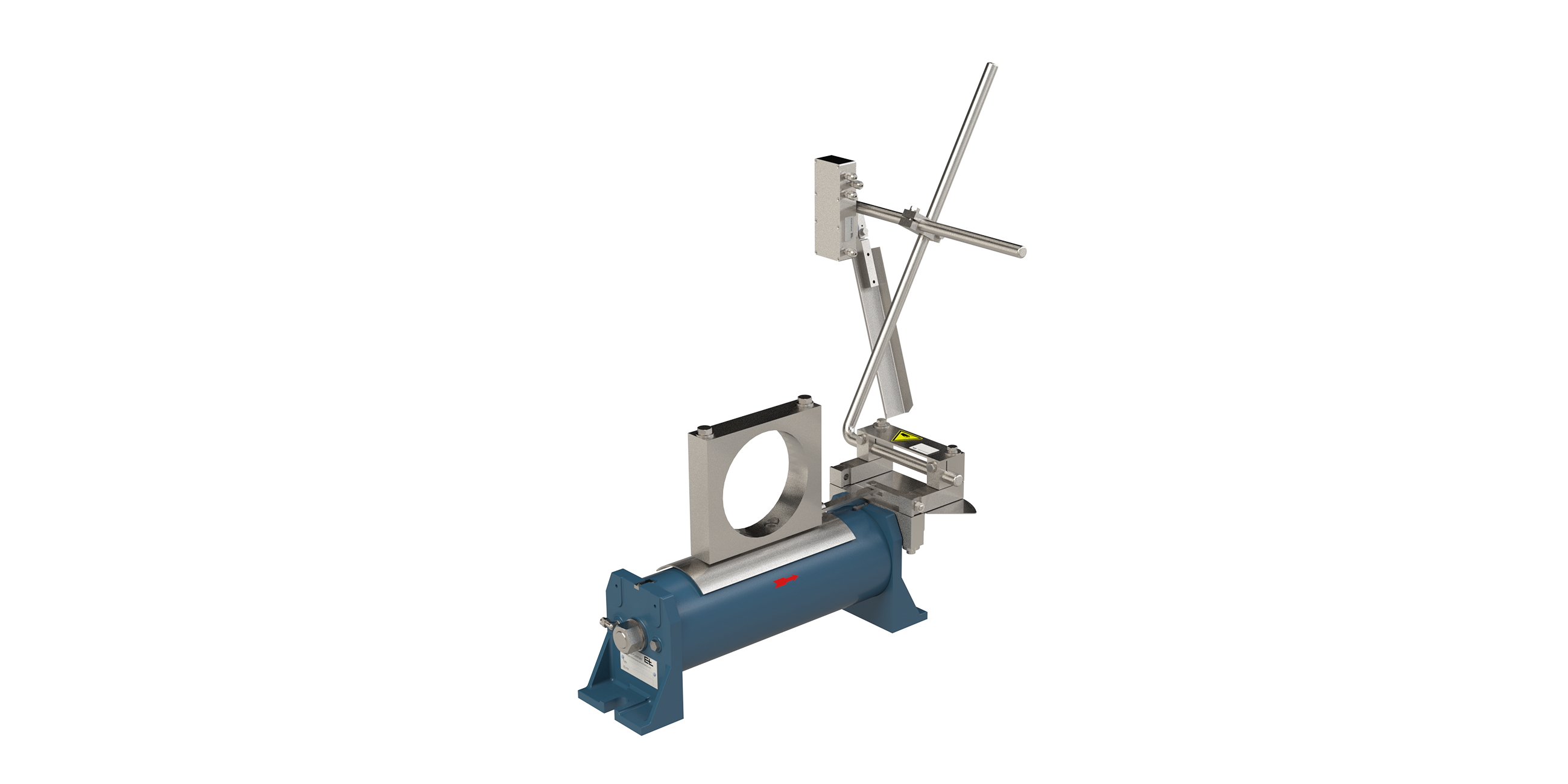

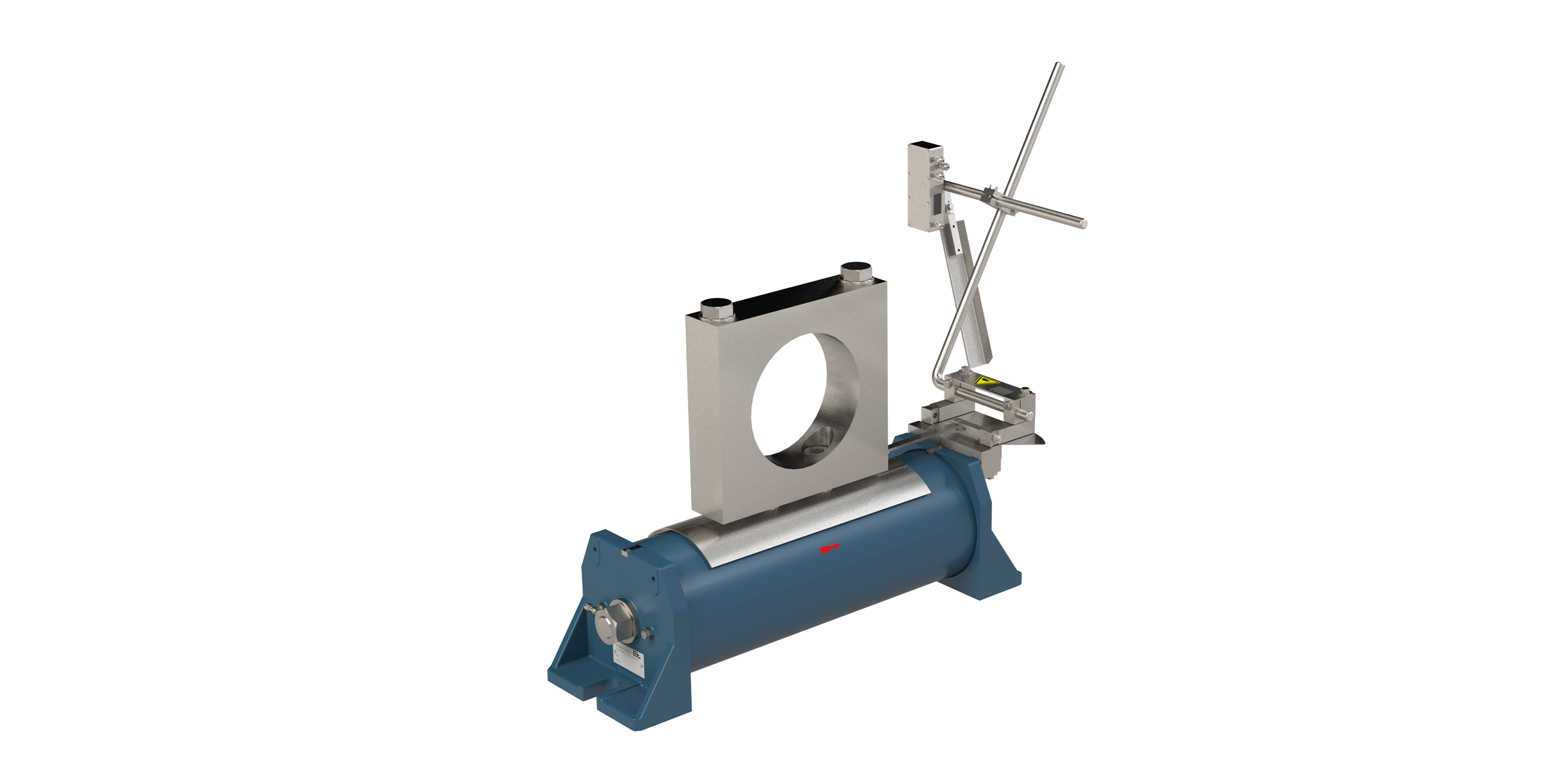

- Description

- Function drawing

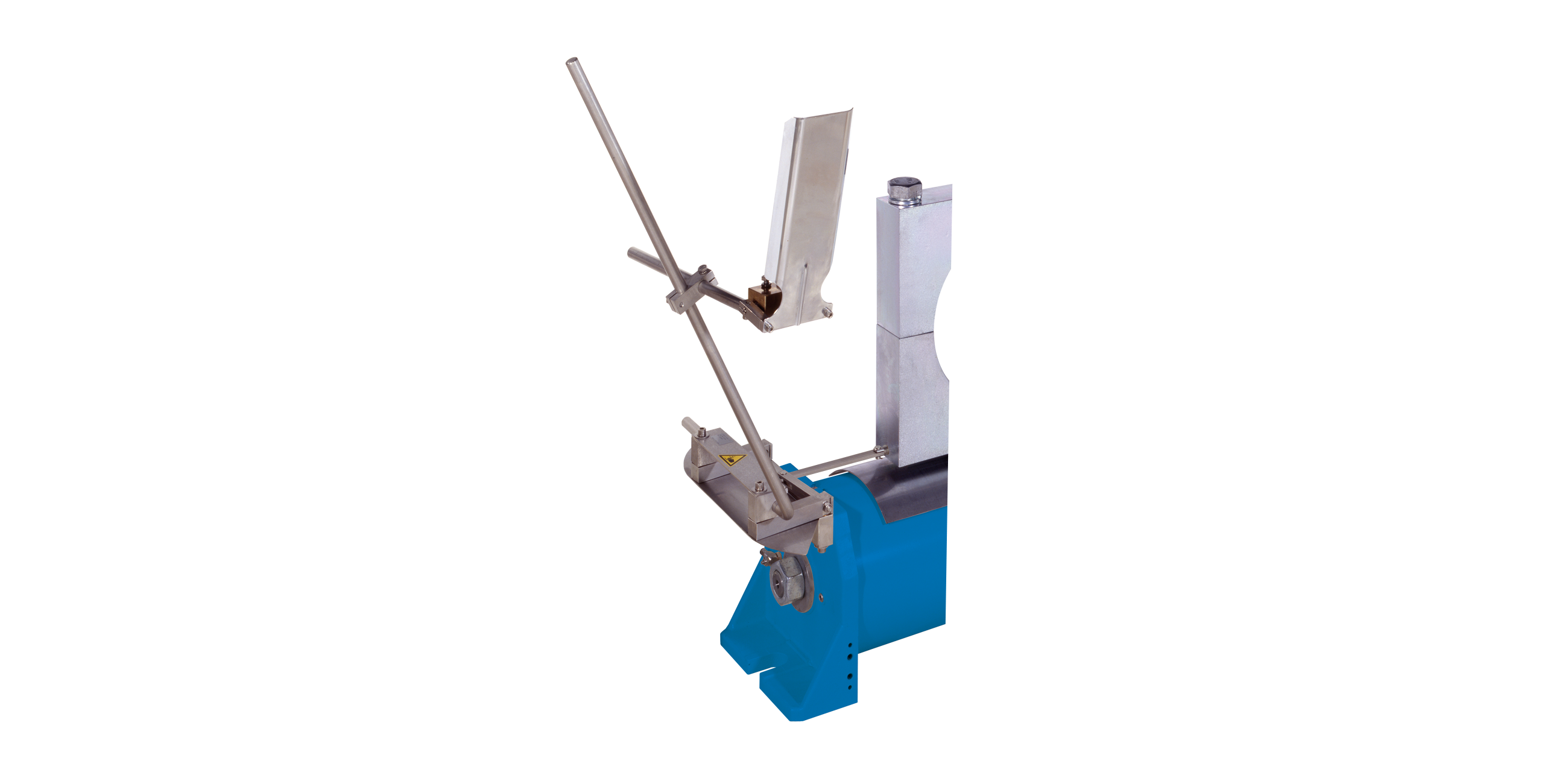

Function

Rollers that are at an angle to the direction of fabric travel cause the fabric to drift laterally. Here, the pivot point for the control roller is one of the two bearings at the ends The control roller is positioned at an angle around this point depending on the correction required. Mechanical or electrical regulating variable feedback delivers a stable closed-loop control circuit.

Area of use

Felt and wire guides are used to hold the clothing in the required position.

Application

The positioning roller requires a feed length corresponding to around 2/3 of the clothing width. The outfeed length should be around 1/3 of the clothing width. The clothing must wrap around the positioning roller by between 20° and 40°, with the infeed angle being less than or equal to the outfeed angle. The edge sensor should be positioned in the outfeed path as close as possible to the positioning roller.

Legend

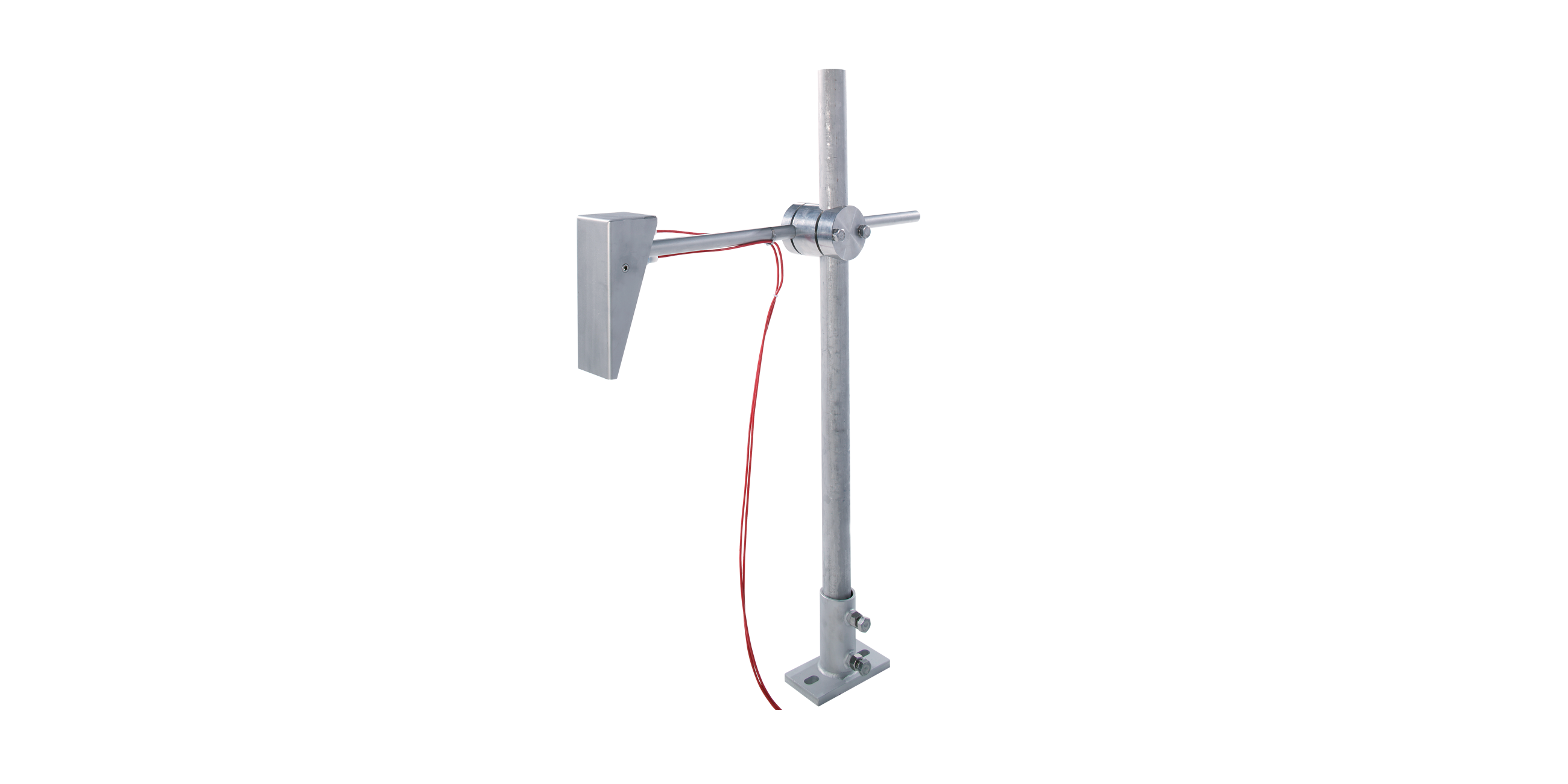

FB = Fabric width | α = Infeed angle | β = Outfeed angle | L1 = Infeed path = | L2 = Outfeed path | FB = Web tension | FS = Actuating force | FG = Weight force, positioning roller | FR = Resulting web tension | 1 = Control roller with fixed bearing | 2 = Infeed roller | 3 = Controller roller | 4 = Actuator with floating bearing | 5 = Edge sensor | 6 = Outfeed roller