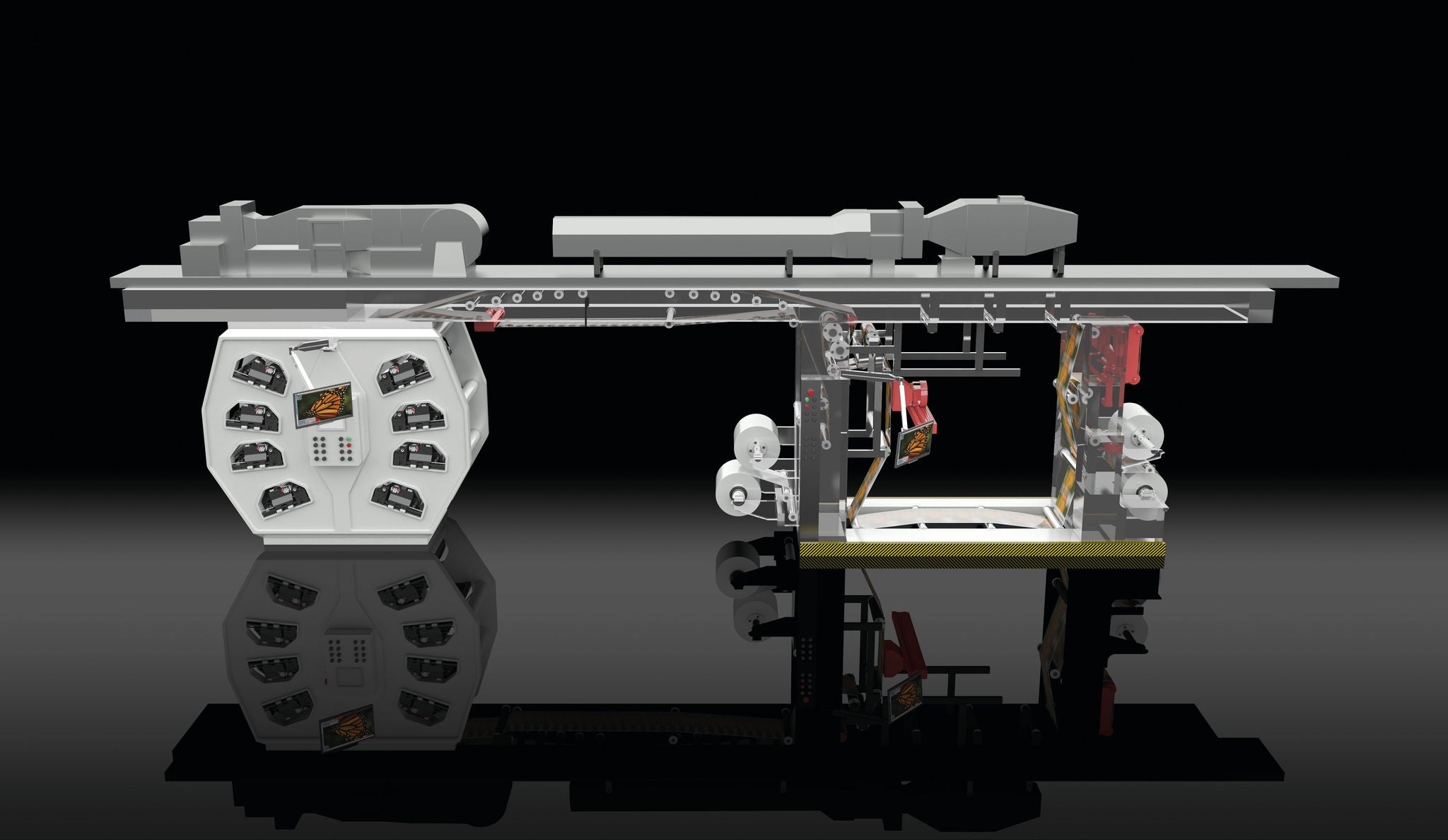

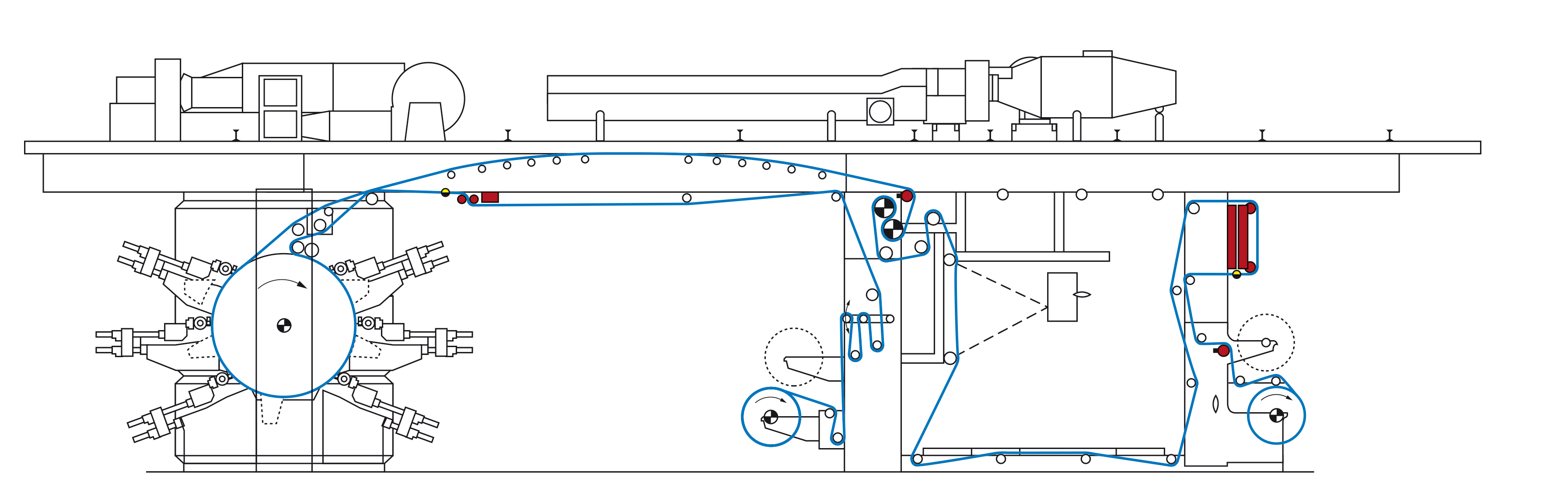

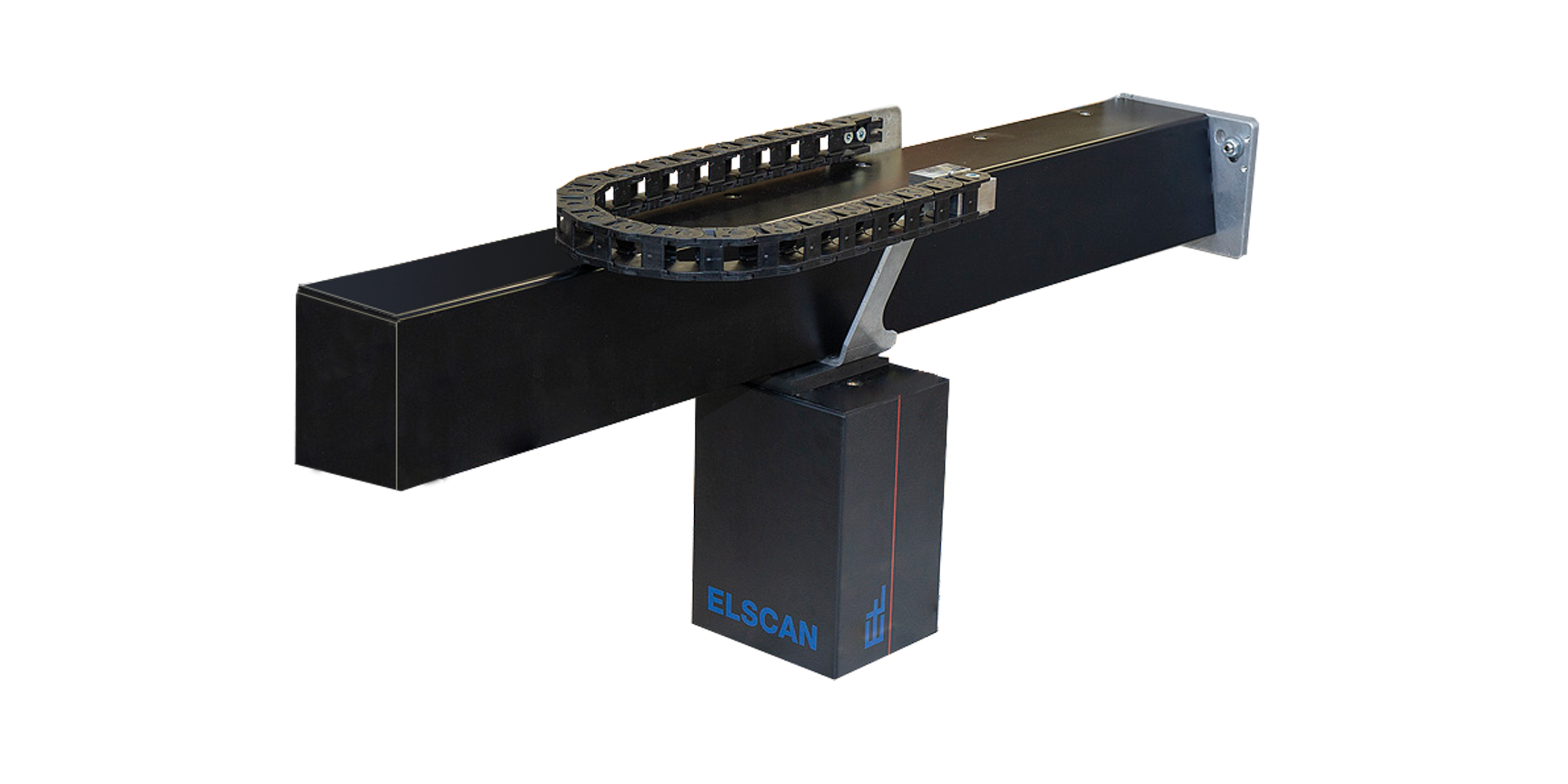

Today, an efficient production process is crucial for economic success in packaging printing. Comprehensive automation of the individual production steps is the means to this end. Whether precise web guiding, even web tension or quality assurance – with solutions such as the innovative double-camera web monitoring, ELSCAN OMS6, you secure the best results in relation to quantity and quality. Thanks to our new EL.NET technology, E+L products in the machine can be very straightforwardly connected to a network, either directly or indirectly via the PLC. In this way, for instance, operation from various positions at the machine is possible, as well as much more! Hardware savings and improved ease of use provide clear cost advantages.